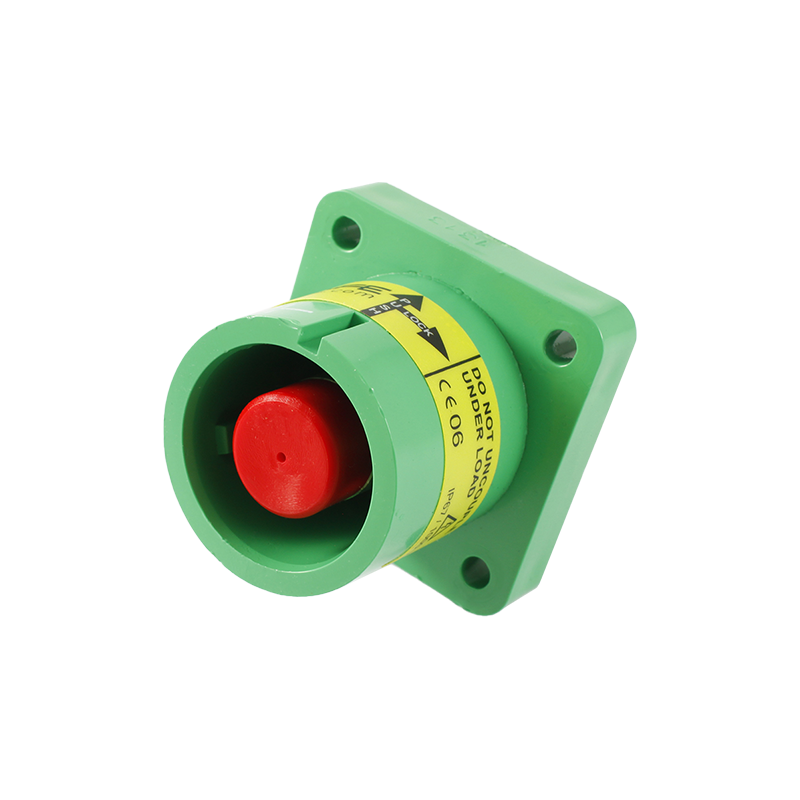

Panel Mount are secured with an M12 threaded post termination. The standard connector is mounted to a panel through 4 fixing holes on the flange. As an alternative, flange holes can be fitted with M6 threaded inserts for either front or rear fixing. Panel connectors are supplied fully assembled and ready for direct mounting to equipment.

1. When the panel Connector is mounted in equipment: remove the nut and washer from the threaded post section.

2. Fit your selected terminal or accessory (i.e lug) over the threaded area.

3. Refit the Washer and bolt on to the threaded area and tighten to a maximum of 12 – 14Nm.

For more information on terminations and assembly, view our

Powersafe Assembly Guide.

Powersafe industrial sockets are rated either 500 amp (T5) or 800 amp (T8).

The ‘T’ stands for Threaded Post Termination. The ‘5’ and ‘8’ stand for 500A and 800A respectively.

The Powersafe Power Distribution Box comes with an optional Lid as an extra. The product lid ensures an IP67 rating when not in use and protects the box from the environmental damage.

As the box is often left unused as a backup for power outages, it is recommended that the lidded version is purchased.

The Powersafe Sequential Mating Box has a straight front panel that comes in two panel sizes, 88mm and 108mm.

88mm (2U) box: H= 88mm, W= 483mm, D= 130mm

108mm (4U) box: H= 108mm, W= 483mm, D= 130mm

Within different racking and panel mounting applications different sizes are required.

Phase 3’s Compliance Manager, Lee Corrigan, who led the project for UL approval said, “It’s been an enjoyable challenge gaining UL approval for myself and the team, who have worked extremely hard on this project. It’s great for the product to be recognised for its safety features and high quality. We feel this will help open many doors in the US and other markets for us as it’s now one of the highest rated single pole connectors with UL approval.”

UL Certification is usually required in the USA and Canada.

Powersafe UL Connectors are rated slightly lower to match with UL Certified power cable current ratings – this helps users avoid confusion and adhere to UL testing standards. Our standard 500A connectors are downgraded to 455A and our standard 800A connector is downgraded to 615A.

In line with the adjusted ratings, UL Connectors are only available for devices with terminations below Crimp 150mm2 and Set Screw 120mm2.

View the Powersafe UL Certificate